Established, Emergent, Agile, Sustainable?

An ECI Conference Series

Single Use Technologies VII Volunteer Form

September 10-13, 2023

Hyatt Regency Hotel

Boston, Massachusetts, USA

Poster Size: 1.0 meter wide and 1.5 meters in length (Portrait style)

Covid-19

We expect everyone attending this conference to be up-to-date on their vaccinations against Covid-19 and its variants. Anyone who is not fully vaccinated should have a PCR test done before they travel to the conference and bring the negative results with them. We suggest that everyone attending the conference should bring a Covid home test kit with them to use in case they feel unwell. If anyone tests positive on site, they should stay in their room and notify the ECI staff on site.

About this Conference

Single-Use Technologies VI is the sixth event of an ECI conference series started in 2015 and unique in its aim – to advance knowledge in the fundamental science and engineering underpinning Single-Use Technology (SUT).

The conference will be a 4-day event and will target 100-120 attendees. The conference will have speakers and attendees from industry and academia, single-use final product (e.g., bags, assemblies) manufacturers, film/resin manufacturers as well as keynote speakers from the biopharmaceutical industry, experts in polymers/materials science, and manufacturers of novel biomedical devices. Regulators are also invited to speak and attend.

This conference will build on the success of the previous editions and will focus on four key themes: Established, Emergent, Agile, and Sustainable. “Established” and “Emergent” refer to both therapeutics (ie, established therapeutics like monoclonal antibodies as well as emergent cell and gene therapies) and single-use technologies (ie established films as well as emergent sensors). “Agile” encompasses operational change across the industry – how do we enable agility in our operations? “Sustainable” reflects the industry-wide intention to use SUT in a sustainable manner, and the need to tackle the challenge collectively.

This conference brings together a multidisciplinary community interested in collaborating openly towards the advancement, expansion, and environmentally responsible use of single-use technology in the bioprocessing industry. The organizing committee welcomes the submission of scientific work that is novel and high quality.

Conference Organizers

Conference Chairs

Magali Barbaroux (Sartorius)

Magali Barbaroux completed her Ph. D. at the University of Paris in Material Science, and Engineering She has over 25 years of experience in polymer science for healthcare applications. She started her career with research into silicone for drug delivery and migration of active substance through polymeric membrane. She joined Sartorius in 2000 and contributed to the development Single-Use products optimized for bioprocessing applications. She now belongs to the Sartorius Corporate Research and manages the Advanced Polymers related research programs, with a strong focus on environmental sustainability and opportunities brought by the New Plastic Economy in biotech applications.

Sheryl Kane (Takeda)

Sheryl Kane is the head of the Strategic Materials Assurance Group at Takeda in Lexington, MA. She has a B.A. in Chemistry and a Ph.D. in Bioengineering, with a focus on polymers. She spent the first half of her career in R&D related to medical devices, drug delivery, and filtration membranes, then moved into biotechnology to support single-use systems and raw materials for bioprocessing. She is focused on proactive raw material improvements and identifying and implementing solutions to material challenges within Takeda and the biotech industry.

Seongkyu Yoon (University of Massachusetts, Lowell)

Dr. Seongkyu Yoon is a Professor in the Francis College of Engineering at the University of Massachusetts (UMass), Lowell which he joined in 2010 after 15 years in industry. Currently, Dr. Yoon is co-director of Massachusetts Biomanufacturing Center, the UMass site director of the NSF/IUCRC/AMBIC, the co-PI of NSF/AccelNet/IBioNe (International Biomanufacturing Network), and the UMass technical lead for NIST-sponsored Manufacturing USA institute NIIMBL. Dr. Yoon founded the Massachusetts-based Biomanufacturing Innovation Institute for universities and companies. Yoon is leading a research group of systems and synthetic biology while conducting researches in platform process development for protein, gene and vaccine therapeutics. He completed his PhD at McMaster University (Hamilton, Canada).

Steering Committee Members

Weibing Ding (GSK)

Regine Eibl-Schindler (Zurich University of Applied Sciences)

Beth Junker (BioProcess Advantage LLC)

Gary Lye (University College London)

Ekta Mahajan (Genentech-Roche)

Martina Micheletti (University College London)

Robert Repetto (Pfizer)

Keynote Speakers

William E. Bentley

(University of Maryland)

Keynote Title: Bio <=> Electronic Information Processing: An Emerging Technology for Biomanufacturing

William E. Bentley is the Robert E. Fischell Distinguished Chair of Engineering, the Inaugural Director of the Robert E. Fischell Institute for Biomedical Devices, and Director of the Maryland Technology Enterprise Institute (Mtech). His primary appointment is in the Fischell Department of Bioengineering, a department he founded. He is also appointed to the Department of Chemical and Biomolecular Engineering at the University of Maryland, College Park and the Institute for Bioscience and Biotechnology Research. At Maryland since 1989, Dr. Bentley has focused his research on the development of molecular tools that (i) facilitate the expression of biologically active proteins, and (ii) with tools of synthetic biology and materials engineering, open lines of communication with electronics, having authored over 375 related archival publications. His interests also include translation of technology; he co-founded a company (Chesapeake PERL) exploiting caterpillars as mini bioreactors for the synthesis of recombinant proteins, including vaccines. He is a Co-PI of the Advanced Mammalian Biomanufacturing Innovation Center (AMBIC) and is a regular contributor to the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL) ecosystem. He is a fellow of AAAS, ACS, AIMBE, and the American Academy of Microbiology. He has served on advisory committees for the NIH, NSF, DOD, DOE, FDA, USDA, and several state agencies and has mentored over 40 PhDs and 25 postdocs, many now in leadership roles within industry, federal agencies, and academia.

John E. Schiel

(National Institute of Standards and Technology )

Keynote Title: Big Ideas, Bold Goals, and the Future of Biomanufacturing

Dr. Schiel received his BS (2004) and Ph.D. (2009) in chemistry from the University of Nebraska-Lincoln, and is currently serving as the Federal Technical Program Manager for NIIMBL, a Manufacturing USA institute accelerating adoption of advanced biomanufacturing technologies. Dr. Schiel also maintains a research lab in the NIST Biomolecular Measurement Division. Dr. Schiel coordinates the NISTmAb program and leads an analytical research team developing innovative approaches toward production/characterization of next generation biotherapeutics. He is an author of over 45 publications and national strategy reports, an editor of three books, and recipient of numerous Awards including the Department of Commerce Gold Medal and the Arthur S. Flemming Award.

Conference Agenda

Session Descriptions

Session “Established”

The established space includes both established technologies and established therapeutics. Over the past decade, single-use systems have gone from cutting-edge to the default technology for new facilities making protein therapeutics such as monoclonal antibodies. For these applications, the focus is on improvement and lifecycle management at both suppliers and end users. How do you set up a greenfield single-use facility? How do suppliers introduce new technologies and manage changes to existing technologies? How do end users improve their design libraries and incorporate new technologies? How do end users address risk (real and perceived) and regulatory considerations when making changes? Where do you want to see established single-use technologies go next?

Session Chairs:

Gary Gilleskie (NCSU)

Gary Gilleskie is the Executive Director of North Carolina State University’s Golden LEAF Biomanufacturing Training and Education Center (BTEC) – a unique center whose mission is to develop skilled professionals for the biomanufacturing industry. Since joining BTEC in 2007, Gary has developed and taught numerous courses in the area of downstream biopharmaceutical process development and manufacturing for university students, industry professionals, and various regulatory agencies throughout the world. Among those courses is Hands-on Single-use Processing for Biopharmaceuticals, a short course taught annually for industry professionals. Prior to joining BTEC, Gary spent 15 years in both the chemical and biopharmaceutical industries, most recently at Diosynth Biotechnology (now Fujifilm Diosynth Biotechnologies). He received his B.S. in chemical engineering from NC State University in 1986 and his Ph.D. in chemical engineering from the University of Minnesota in 1993.

Sandrine Egli (Lonza)

Sandrine Morgenstern-Egli is an Associate Director in the Single-Use Technology team within the Lonza global Manufacturing Process Technology and Innovation group. After a start in the field of stem cell research, she joined the pharmaceutical industry environment where she worked on the development of a continuous manufacturing process and on cell line

development within Novartis Pharma AG. She then transitioned to Hoffmann-La Roche Ltd where she started in the field of commercial manufacturing operation and held several roles in

technical operations such as facility start-up projects or technical transfers projects. Sandrine Morgenstern-Egli holds a Master of Pharmaceutical Biotechnology from the Zürich University of Applied Sciences, Switzerland.

John Puglia (ThermoFisher)

Session “Emergent”

The emergent space includes both emergent technologies and emergent therapeutics. While single-use systems are the default technology for many newer therapeutics such as cell and gene therapies and mRNA products, the new applications warrant a closer examination of their fitness for purpose. Many of the enabling technologies were developed for research purposes, and they are not as mature as those used for protein production. Others have been repurposed from protein production or medical device industry but may not perfectly meet emergent therapeutic needs. The supply base associated with these technologies is also emergent. In the technology space, what new technologies are under development? What are the technology and compliance gaps, and how are we addressing them as an industry? How are end users and academics using single-use technology to enable new therapeutic production? Where do you want to see emergent single-use technologies go next?

Session Chairs:

Mark Blenner (UDEL)

Dr. Blenner is an Associate Professor of Chemical & Biomolecular Engineering at the University of Delaware. Prior to that, he was the McQueen Quattlebaum Associate Professor of Chemical and Biomolecular Engineering at Clemson University. He received his PhD in Chemical Engineering from Columbia University in 2009 and completed three years of postdoctoral training as an American Heart Association Postdoctoral Fellow and an NIH NRSA Postdoctoral Fellow at Harvard Medical School and Children’s Hospital Boston. His research is broadly focused on engineering microbial and mammalian cells systems for the production of biopharmaceuticals, nutraceuticals, chemicals, and biosensors. He is applying synthetic biology and systems biology to improve mammalian cell line development and cell line stability.

Shawn Wang (Kite Pharma)

Shawn (Xueyuan) Wang is an Associate Director in Kite Pharma Process Development. He leads the raw material group in Kite’s PD focusing on new material development and implementation into Kite clinical programs. He has a B.S. in Biology from University of Science and Technology of China and Ph.D. in Polymer Engineering from the University of Akron. He started his career in a polymer film R&D company, then moved to the pharmaceutical industry to work as single use system SME. He supported the single use facility build up in both Genentech and Bayer before moving to Kite to focus on cell therapy applications.

Takeshi Nishiura (Northwest Fluid Solutions)

Takeshi Nishiura is the head of single-use technologies at Northwest Fluid Solutions. He has a B.S. in Chemical Engineering from University of California, Los Angeles. He has over 17 years of biotechnology industry experience, the bulk of which has been focused on making single-use systems successful in biologics and cell therapy manufacturing from the end user perspective. He joined Northwest Fluid Solutions in 2022 and is now focused on applying his experience to the supplier side of the industry and providing robust bioprocessing solutions to serve customers and their patients.

Session “Agile”

One of the many benefits of single-use technology is the potential to adjust quickly to changes in market demands and operational requirements. Single-use technology can provide simplified and flexible production with less time, energy, labor, resources and capital. It is an agile technology that can allow patients around the world better access to new and existing medicines by enabling manufacturers to deliver these therapies faster.

Some of the questions we seek to discuss in this session are: How do you enable agility in a GMP facility? How do suppliers enable agility in their own technologies, products, and operations? What are the regulatory considerations that may support or limit agility? What are the fundamental concepts required to enable agility? What does agility mean to you?

Session Chairs:

Andrea Rayat (UCL)

Andrea Rayat is Associate Professor in Bioseparations and DSP at University College London (UCL). She holds Biochemical and Chemical Engineering degrees from UCL (PhD), TU Delft (MS), and UPLB (BS). She leads a research group that studies and develops scale-down methods to investigate primary recovery and membrane processes in the manufacture of biotech products. Her work interfaces with technology translation and knowledge exchange having previously secured an EPSRC Impact Acceleration award and Innovate UK’s Knowledge Transfer Partnership. The latter won for their team an Institution of Chemical Engineers (IChemE) global award in 2020. Currently, she is PI in a BBSRC project where she studies single use/re-usable membrane materials and the yield of vector production for gene therapy. At UCL, Andrea is the head of the department teaching committee and is director of the BEng/MEng Biochemical Engineering programs.

Christian Wood (Moderna)

Christian Wood is a Director of Critical Materials MS&T at Moderna, where he leads a group that supports the life cycle of single use consumables and raw materials. He’s worked in various process development and manufacturing support roles for over 18 years in biologics, cell therapy, and vaccine manufacturing. His work in process and technology development, capital projects, and manufacturing support has consistently had a strong emphasis on single use consumable design and optimization. He has BS and MEng degrees in Chemical Engineering from Cornell University.

Jeffrey Carter (Cytiva)

Jeff Carter has been a supplier to the bio/pharmaceutical manufacturing industry for over twenty-five years, and he has been with Cytiva/GE Healthcare since 2005, serving in R&D and Marketing capacities. His present role as Consumables Strategic Projects Leader is to lead initiatives that focus on augmenting quality and supply of our single use portfolio. He is active in organizations such as ASTM E55, ASME-BPE, and BioPhorum. He is Chairman Emeritus of the Board of BPSA. Dr. Carter holds a PhD degree from Penn State University in molecular microbiology.

Session “Sustainable”

This session will focus on the integration of environmental sustainability priorities and circularity opportunities in bioprocesses using single-use technology (SUT) and lifecycle analysis (LCA). It will include case studies along the product life cycle: raw material, design, manufacturing, use, end-of life (including recycling), transport, and systems analysis. Key questions that will be addressed in this session include: How to reduce environmental impact of SUTs? What are the levers and approaches to environmental impact reduction? What are the barriers and how can we overcome them as an industry? What does environmental sustainability mean to you?

Session Chairs:

Margaret Sobkowicz-Kline (UMLowell)

Meg Sobkowicz-Kline is a Professor of Plastics Engineering at UMass Lowell. She holds a B.S. and Ph.D. in Chemical Engineering from Columbia University and Colorado School of Mines, respectively. In 2010 she was awarded a National Research Council postdoctoral fellowship to study polymeric materials for photovoltaic applications at National Institute of Standards and Technology, and she joined UMass Lowell in 2011. Her research interests include renewable polymers, blends and composites, plastics processing and recycling, rheology, green chemistry, and climate change. At UMass Lowell she serves on the leadership team for the Office for Faculty Equity, aimed at increasing the participation and advancement of underrepresented groups in academic STEM careers. She is also the PI of an NSF research traineeship project focused on convergent graduate education in water and materials sustainability.

Philip Smith (GSK)

Nelly Montenay (Sartorius)

Nelly Montenay is Head of Material & Science for the Product development group in BPS Sartorius. Nelly is specialized in polymer sciences and polymer transformation with a strong background in film & tube extrusion. She received an Engineering degree in Polymer Sciences from the French ITECH Lyon Engineering School in 2003. With 20 years of experience in Polymer science, film development and product qualification testing, Nelly and her group are advocating Material sciences within Sartorius. With a strong interest in communication skills and people, Nelly plays also a key role in supporting projects & exchange within international groups.

Poster Committee

Caitlin Morris (UMLowell)

Stephanie Ketcham (BMS)

Stephanie Ketcham is a Principal Scientist for Bristol Myer’s Squibb’s BioProcess Technology Manufacturing Sciences and Technology team. She leads the upstream lab-based manufacturing support team for the single-use facility (SUF). The expanding scope of commercial and clinical molecules within the SUF brings new PAT technologies and innovative process strategies for biologics manufacturing. Stephanie has a Ph.D. in biology from Johns Hopkins University, where she trained as a cell biologist and biochemist. She transitioned from basic research science to bioprocessing while a post-doc at the FDA, focusing on common process changes and their impact to product quality.

Brendan Lucey (Entegris)

Brendan Lucey oversees the go to market strategy at Entegris. I have been on the board of Bioprocess systems alliance and now am the chair of the Cell and Gene Therapy Committee. A biologist by training now working in the single use field (Lonza, Sartorius, ILC Dover) to improve the way new therapies are made. I am proud of the work I have done to help get medicines to market faster and more safely to improve lives all over the world and look forward to doing more.

Poster Awards

First Place

Chad Varner

Sanofi, USA

Developing a universal single-use skid for continuous purification operations

Tied for Second Place

Armin Hauk

Sartorius-Stedim Biotech GmbH, Germany

A mathematical approach to evaluate equivalence in E&L assessments of SUS

Robert Barrentine

Saint-Gobain Life Sciences, USA

Environmental impacts of gamma versus X-ray irradiation sterilization

Abstract Submissions

One-page abstracts should be submitted as soon as possible and no later than the deadlines noted below. The abstract should include both the significance of the research as well as results that will be discussed in order to allow a scientific assessment of the work by the organizers. Please indicate the most relevant session topic for which you are submitting your abstract and whether the abstract should be considered for an oral or poster presentation.

The specific topics are (sessions are described above):

Session “Established”

Session “Emergent”

Session “Agile”

Session “Sustainable”

Only a limited number of oral presentation slots are available. Thus all submissions for oral sessions will be considered for both oral and poster presentation.

All abstracts should be submitted electronically HERE.

Please prepare your abstract according to this template: docx or doc.

Oral Presentation Abstract Deadline: March 1, 2023

Poster Presentation Abstract Deadline: August 18, 2023

Pre-Conference Workshop

(Content in progress)

Sunday, September 10, 2:00 to 5:30

Session chair: Miriam Monge, with Nelly Montenay and Stephanie Ketcham

Pre-Conference Workshop Registration Fee: $150 (includes coffee break and small bites).

Overview

This workshop aims to address four key industry challenges that the single-use bioprocessing industry is currently facing. Through short fire introductions followed by guided moderated interactive breakout sessions, the sessions aim to provide specific learning objectives for each industry challenge. Don’t miss out on this highly interactive learning opportunity with industry experts.

Session 1 – Risk assessment, Annex 1 and new modalities

Session leader: Lorraine Borland, Sartorius, Manager of Process Technology

Co-lead: Nelly Montenay

Addresses industry challenges: Addresses key pharma industry challenges; reducing cost of goods, providing flexible solutions to meet product diversity, complex manufacturing needs, and reducing time to clinic through reduction in validation burden.

Abstract

- The recent release of EU Good Manufacturing Practice (GMP) Annex 1 brings into sharper focus and with greater specificity the expectations from regulators of a drug manufacturer’s implementation of Single Use Technologies. This session focuses on how to form a regulatory strategy for Single Use materials Quality Risk Assessment and how drug manufacturers can leverage single-use supplier information to streamline the process and improve GMP compliance.

- A path forward for meeting Annex 1 contamination control strategy requirements: leveraging SUS product certification; assessing sterility, extractables and Leachables, and control of integrity and robustness will be explored.

Key Learning Objectives

- Understand the specific risk factors for SUS implementation as outlined in EP Annex 1

- How to form a regulatory strategy based on a Quality Risk Management approach

- Specific requirements for SUS product quality, sterility, extractables & leachables, & integrity and robustness across new modalities

Session 2 – Sustainability

Session leader: Shwetha Ravi Devine, Lead Process engineer, DPS Global Engineering

Addresses industry challenges: For manufacturers producing ATMPs, SUT allows greater flexibility in a shorter time frame enabling biopharma innovators, CDMOs and CMOs to set up production lines quickly, in a cost effective, aseptic manner to respond rapidly to unexpected events such as the Covid-19 pandemic.

Abstract

With the biopharma industry under pressure to build a more sustainable future, any reduction in use of renewable resources or plastic as in single use technology (SUT) can bring us one step closer to achieving that goal. As the name suggests, SUT are made from high-performance polymers, used once, and disposed, typically heading to a landfill or incineration. When items made from these polymers go to landfill, they may take hundreds of years to decompose, polluting soil and water with harmful contaminants in the process. Incinerating plastics releases harmful emissions and pollutants that adversely affect the environment and human health. This leads to a common belief that SUT must be detrimental to the environment and therefore not sustainable. However, those dismissing SUT based on environmental reasons in favour of stainless-steel technology are missing the full picture.

Key Learning Objectives

- How sustainable are Single Use Technologies?

- Comparison with traditional SS in understanding the pros and cons of SUTs.

- What does the future hold for novel therapeutics and ATMP manufacturing?

Session 3 – Standardization of Single-use Designs

Session leader: Alex DiBenedetto, Global Manufacturing Science & Technology (PTT), Roche-Genentech

Co-lead: Shawn Wang, Kite Pharma Process Development

Addresses industry challenge: This session will seek to address the challenges with regards to harmonization of single-use designs across manufacturing sites and indeed across the industry. What step change needs to happen to achieve greater SUS harmonization and how will this ultimately lead to a more robust supply chain?

Abstract

- Design flexibility and customization of Single Use Systems (SUS) have resulted in the proliferation of many specialized SUS designs across the biomanufacturing industry and even within biomanufacturers.

- SUS design flexibility and customization have created supply chain complexity and constraints, requiring significant resources from both suppliers and biomanufacturers to manage large inventories of custom SKU’s

- SUS design standardization has mutual benefits for suppliers and biomanufacturers, who agree that a higher level of standard, modular designs is required for continued industry success. However, an industry-wide actionable framework for SUS design standardization still does not exist.

Key Learning Objectives

- Discuss key barriers and benefits to SUS standardization

- Identify opportunities for SU component reduction / standardization

- Identify opportunities for SU assembly design standardization

Session 4 – Industry Forum Overview and Updates on Active Workstreams

Session leader: to be determined

Addresses industry challenge: coordination and alignment of best practices, standardization, collaboration in the industry.

Conference Fees and Registration

Conference Fees

All conference fees are inclusive. They include registration (conference and pre-conference workshop), accommodations (nights of Sunday (Sept. 10), Monday (Sept. 11), and Tuesday (Sept. 12)), all meals, excursion, taxes, and gratuities from the reception and dinner on Sunday through lunch on Wednesday. Incidental fees (telephone calls, faxes, spa, laundry, minibar etc.) are billed to your personal account by the hotel.

ALL PARTICIPANTS (INCLUDING MEMBERS OF THE ORGANIZING COMMITTEE AND INVITED SPEAKERS) ARE REQUIRED TO REGISTER.

The conference fees are:

| Register June 23, 2023 | Register June 23, 2023 | |

| Participant (single occupancy or sharing room with a guest; guest fee additional) | US $2,995 | US $3,300 |

| Participant (sharing a room with another participant) | US $2,490 | US $2,800 |

| Bona fide Graduate Student (sharing a room with another student) (Those in this category must upload proof of current status during registration – copy of current Student ID or a letter from your University confirming your student status) | US $1,040 | US $2,385 |

| Bona fide Graduate Student (single occupancy or sharing room with a guest; guest fee additional) (Those in this category must upload proof of current status during registration – copy of current Student ID or a letter from your University confirming your student status) | US $2,580 | US $2,890 |

| **Fees for Guest/accompanying person sharing bedroom with a participant. (Includes all conference included meals and excursion) | US $855 | US $855 |

If you plan to bring children to the conference, please contact Kathy Chan for pricing.

Conference Registration

You will need a login name and password to register for ECI conferences through our online system. If you have been a recent participant at an ECI conference or have submitted an online application or request for information about an ECI Conference, you may already have an account with us. If you know your login information, please use it.

If you are not sure whether you already have a login and password, please click on automated password retrieval and enter your e-mail address before creating a new account. If we don’t have a valid email address on file for you, a pop up window will appear stating that no records were found. Click “OK” and then follow the instructions to create a new account. If you have any questions or experience any difficulties, please email Kathy Chan.

Special Notes and Payment Instructions

We suggest that you register as soon as possible to be certain that you will have a hotel room at the conference rate.

All participants are encouraged to register before June 23, 2023. There is a discounted price for registering before this date. Hotel space cannot be guaranteed for registrations received after this date. Your registration is not officially confirmed until we receive payment of the amount due. ECI reserves the right to cancel your room registration if payment is not received. Your invoice/receipt will automatically be e-mailed upon of receipt of your registration. Should you need a signed receipt, please contact Kathy Chan.

Because of contractual guarantees made with the hotel for room and meal functions, no shows, late arrivals, missed meals and early departures cannot receive fee adjustments. If you have a disability and may require accommodation in order to participate fully in this conference, please indicate this when you register. An ECI representative will contact you to discuss your specific needs. If you have special dietary requirements (e.g., vegetarian or a food allergy), please make a note on your registration. The chef needs to know this information in advance if we are to accommodate you. ECI will attempt to accommodate special requests such as Kosher or Halal meals, but such meals may not be available at all conference sites. The participant must pay any additional costs for special meal requests that ECI pays a surcharge for.

Payment must be made by credit card (Visa, MasterCard, and Amex), check or money order drawn on a U.S. bank in U.S. dollars, payable to ENGINEERING CONFERENCES INTERNATIONAL. Checks or money orders in any other currencies are NOT ACCEPTABLE. Payment must be made on the web site except for those who are sending payment by wire transfer or have a purchase order from their company/institution.

WIRE TRANSFER PAYMENT: If you are planning to make payment by wire transfer, please contact Kathy Chan for the bank information. You must add $30 to cover ECI bank charges. Please reference your full name and the conference title. Please email a scanned copy to Kathy Chan. This is very important – otherwise it is extremely difficult to trace your payment and you may not receive a receipt prior to the conference.

Cancellation Policy: Cancellation must be received by ECI in writing at least 28 days prior to the start of the conference in order for a full refund (less a processing fee) to be considered. The ECI auditors require that refunds for all conference cancellations be processed after the conference so that the necessary back-up information (e.g., hotel list of those in-house) can be attached to the refund request and ECI can verify that the hotel has not charged a cancellation fee.

Cancellation fees:

- Cancellations received more than 28 days prior to the conference start date are subject to a processing fee of 4% of the total fee, plus any direct expenses incurred by ECI.

- Cancellations received 15 – 28 days prior to the conference start date are subject to a $250 cancellation fee plus any direct expenses incurred by ECI.

- Cancellations received 8 – 14 days prior to the conference start date are subject to a $500 cancellation fee plus any direct expenses incurred by ECI.

- No refunds will be issued for cancellations received less than 7 days prior to the conference start date.

- No refunds will be issued due to inclement weather or travel disruptions/cancellations.

Registrations may be transferred without incurring any penalty or cancellation fee.

Denied or delayed visa

If a participant is forced to cancel due to a denied or delayed entry visa, ECI will issue a full refund if ECI has been notified of a potential visa issue at least four weeks prior to the conference start date.

Change of payment method

If an attendee who has already paid the conference fee with a credit card requests that the fee be refunded to that card so that it can be paid in a different manner (e.g., charged to an alternate credit card, or paid via check or bank transfer), a processing fee of 4% of the total fee amount will apply.

Disclaimer

It may be necessary for reasons beyond the control of ECI to alter the content and timing of the program or the identity of the speakers. In the unfortunate circumstance that an event is cancelled, ECI is not liable for any costs incurred by participants in connection with their attendance.

Smoking is prohibited at ECI conferences and conference functions. Should you have specific questions regarding your registration, please contact Kathy Chan

Pre and Post Conference Reservation Form

If you are arriving early or staying after the conference and wish to extend your stay in the conference hotel, please download and complete the Pre/Post Conference Reservation form posted below and send it directly to the conference hotel. ECI does not guarantee or pay for rooms reserved before or after the conference – you must reserve extra nights directly with the hotel and you are responsible for paying the hotel directly for any extra nights.

Corporate Sponsors

Industry Site Tour

After the close of the conference, attendees are invited to visit Repligen in Hopkinton, MA or Landmark Bio in Watertown, MA. The tours will be held simultaneously on the afternoon of Wednesday, September 13, right after the conference ends. Attendees are welcome/encouraged to sign up for one of the tours. Transportation will be provided between the conference hotel and the tour sites. Space at both locations is limited, so we encourage early registration to ensure availability.

- Repligen: Participants are invited to visit Repligen’s single-use manufacturing facility in Hopkinton, MA to learn about Repligen and see firsthand how single-use systems are produced in Repligen’s newly-opened single-use integration facility. The site opened in 2022 and is split between single-use system integration and ligand production.

- Landmark Bio: Landmark Bio brings together the best of industry, academia and research hospitals to translate groundbreaking research into life-changing therapies. The facility tour will be held at Landmark Bio’s headquarters in Watertown, MA to show case its state-of-the-art Innovation and Development Laboratories and GMP manufacturing facility which has all the capabilities necessary to develop and manufacture complex advanced therapies such as cell therapies, viral vectors and mRNAs and usher them into the clinic.

Sign up HERE

Boston, Massachusetts

Surrounded by the Atlantic Ocean and the Charles River, Boston offers an astounding number of activities to you to enjoy prior and post conference. These range from harbor cruises, exploring the U.S.S. Constitution, following the Freedom Trail, visiting museums and university campuses, taking in a game at Fenway Field, or just relaxing at the Boston Commons.

Boston Tea Party Ships & Museum

This floating museum features live actors and interactive exhibits, as well as a chance to dump tea overboard.

Freedom Trail

This 2.5-mile, self-guided tour of American Revolution sites starts at Boston Common and ends at the Bunker Hill Monument.

John F. Kennedy Presidential Museum & Library

Explore exhibits about pivotal moments such as the Kennedy-Nixon debate, the Cuban Missile Crisis, and the space program.

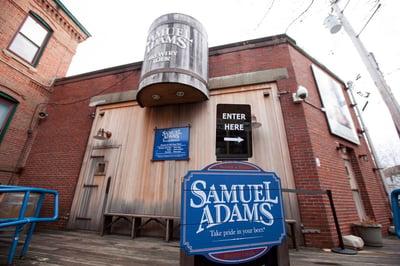

Samuel Adams Brewery

Taste limited-release pints and locally-made snacks in the brewery’s beer garden.

Museum of Fine Arts

Boston’s oldest, largest, and best-known art institution, this museum is renowned for its Impressionist paintings.

Fenway Park

This famous baseball park includes the 37-foot-tall left field wall known as the “Green Monster.”

Isabella Stewart Gardner Museum

A Venetian palace in the middle of Boston, this museum displays a collection of European, American, and Asian art.

Boston Common

Boston’s oldest public park offers a peaceful escape from the busyness of the city.

Boston weather: September is one of the best times of the year to be in Boston as summer shifts into fall. Expect pleasant temperatures and low precipitation.

Previous Conferences

Single-Use Technologies: Bridging Polymer Science to Biotechnology Applications

October 18-21, 2015 – Leesburg, VA, USA

Conference Chairs:

Ekta Mahajan, Genentech Inc., USA

Gary Lye, University College London, UK

Digital Archives

Single-Use Technologies II: Bridging Polymer Science to Biotechnology Applications

May 7-10, 2017 – Tomar, Portugal

Conference Chairs:

Ekta Mahajan, Genentech Inc., USA

Gary Lye, University College London, UK

Regine Eibl, Zurich University of Applied Science, Switzerland

Digital Archives

Single-Use Technologies III: Scientific and Technical Advancements

September 23-26, 2018 – Snowbird, Utah, USA

Conference Chairs:

Weibing Ding, Amgen, USA

Martina Micheletti, University College London, UK

Robert Repetto, Pfizer, USA

Digital Archives

Single-Use Technologies IV: Building the Future Webinar

May 20, May 25, June 1, 2021 – Webinar

Conference Chairs:

Magali Barbaroux, Sartorius, France

Weibing Ding, GSK, USA

Martina Micheletti, University College London, UK

Digital Archives

Single-Use Technologies V: Building the Future

March 20-23, 2022 – Marseille, France

Conference Chairs:

Magali Barbaroux, Sartorius, France

Martina Micheletti, University College London, UK

Digital Archives

General Information About ECI

Engineering Conferences International (ECI) is a not-for-profit, global engineering conferences program, originally established in 1962 that provides opportunities for the exploration of problems and issues of concern to engineers and scientists from many disciplines.

The format of the conference provides morning and late afternoon or evening sessions in which major presentations are made. Poster sessions will be scheduled for evening discussion as well. Available time is included during the afternoons for ad hoc meetings, informal discussions, and/or recreation. This format is designed to enhance rapport among participants and promote dialogue on the development of the meeting. We believe the conferences have been instrumental in generating ideas and disseminating information to a greater extent than is possible through more conventional forums.

All participants are expected both to attend the entire conference and to contribute actively to the discussions. The recording/photographing of lectures and presentations is forbidden. As ECI conferences take place in an informal atmosphere, casual clothing is the usual attire.

Smoking is prohibited at ECI conferences and conference functions.